PREV

NEXT

-

Focused And Therefore Professional

Focused And Therefore Professional -

Aerosol Industry Standard Setter

Aerosol Industry Standard Setter

Views: 6 Author: Site Editor Publish Time: 2021-06-09 Origin: Site

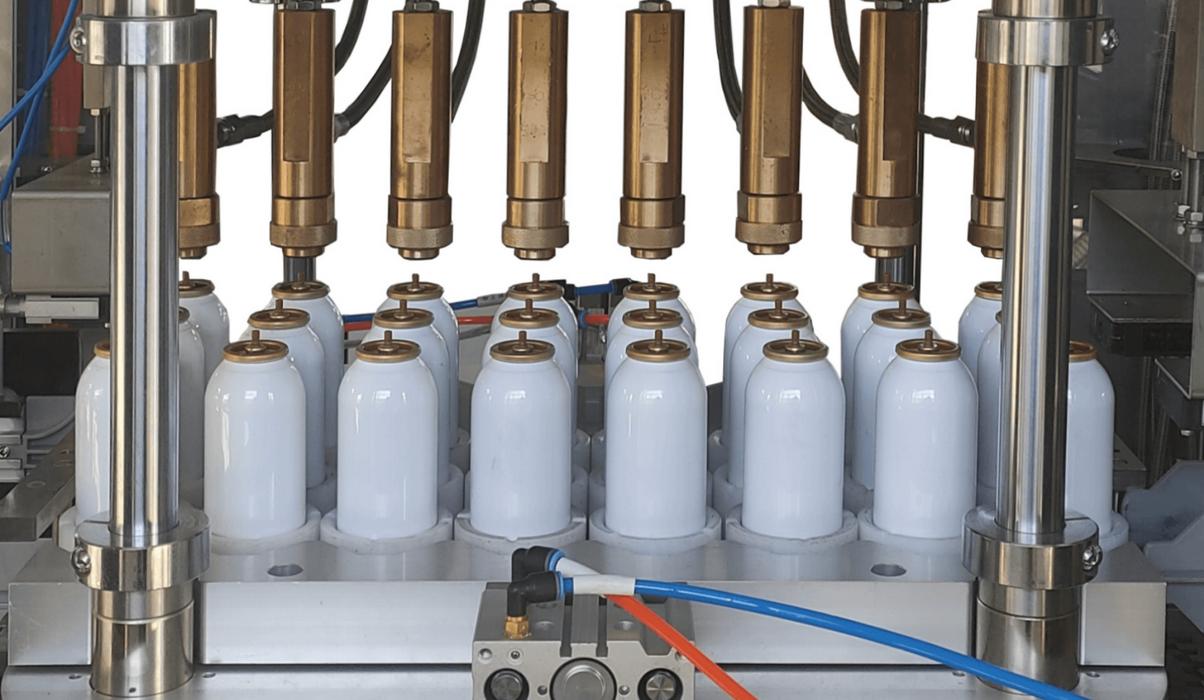

Under the cap filling machine is also called refrigerant filling machine, is a kind of gas filling machine. It is a device specially designed for the bottling method under the cover. And it and the ordinary aerosol tank installation method has a certain difference. The products of Yangzhou Meida Company also have an under cover filling machine. Then, let’s introduce in detail what is an under the cap filling machine?

Here is the content list:

l The working principle of under the cap filling machine

l Advantages of under the cap filling machine

Under cover filling machine uses under cover filling method, also known as under cover filling method. Generally, under the cover filling is to press down the filling head first, then press the lower edge of the filling head and the upper edge of the tank outside the tank mouth tightly, and finally seal. It forms an enclosed space in the interior separated from the outside, in which the valve cover placed above the tank opening is tightened and then lifted. The filling can only be filled in the enclosed space by the gap between the lower part of the valve cover and the top of the aerosol tank opening. It is mainly suitable for filling R134A, R140A and other non-combustible refrigerant products under the cover.

Under the cap filling machine is different from the ordinary aerosol filling machine, it can be filled at the same time, sealing and vacuum pumping. The under-cap filling machine can satisfy the production and filling of all non-core closed valve products. When it is filling, the product must be completed in a vacuum and must be sealed immediately after filling from under the manless valve cover. And it also has a device to recycle leftover material, so it can avoid waste. At the same time, the cap filling machine can not only vacuum, raw material filling and sealing at one time, but also can be used as a sealing machine, with multiple functions.

The advantages are as follows:

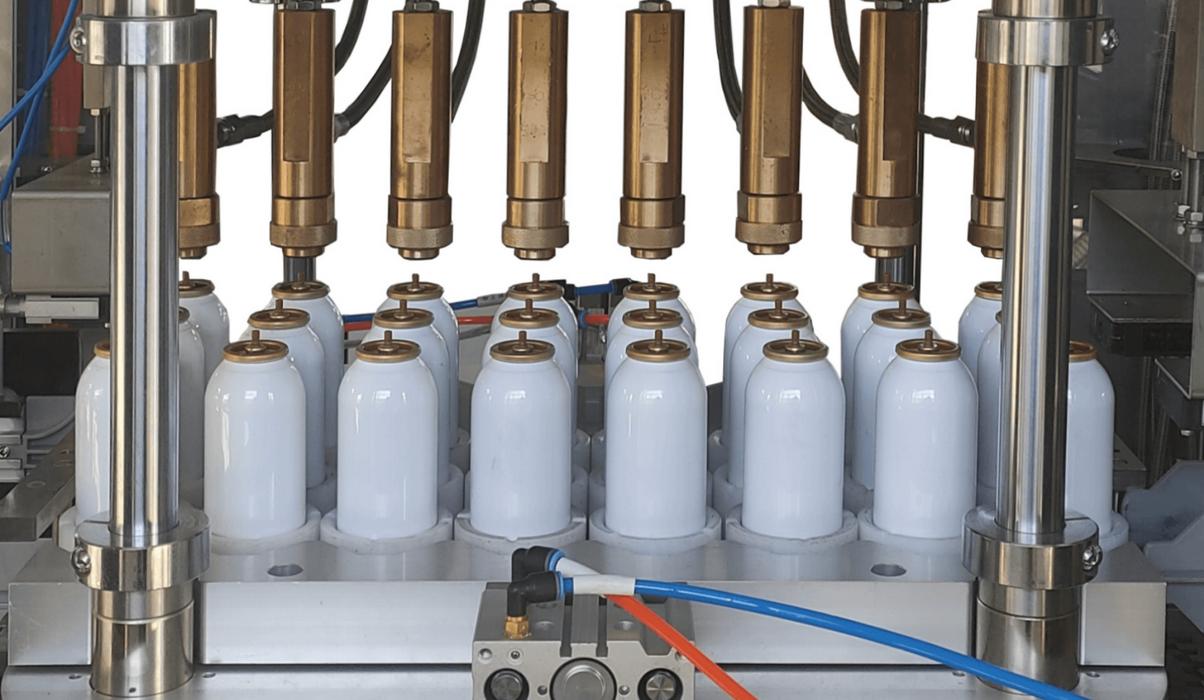

First, no matter what the valve structure is, it will not affect the filling speed of the machine. Secondly, no matter what the internal structure of the valve is, the filling rate is high, uniform and within budget when using the under cap filling machine. Thirdly, the under-cap filling method used by the under-cap filling machine places the sealing net, the projectile agent and the filling structure in one station, and the high speed filling characteristic inherent in the under-cap filling method makes it need less filling head, which not only saves the space but also reduces the maintenance of the machine. And in most cases, the valve with nozzle can be directly used for filling under the cap, saving the bag spray machine. Finally, the under cap filling machine is highly adaptable and any valve supplied by the supplier can be used for under cap filling without the need for special pressing head. There is no need to change the injector filling nozzles when replacing different valve types.

Nowadays, with the continuous development of technology, the development of the under cap filling machine is more mature. People can choose a suitable machine from Yangzhou Meida Company, which is the best choice.

Come to our website to check out more aerosol filling machines and Bov aerosol filling machines!