PREV

NEXT

-

Focused And Therefore Professional

Focused And Therefore Professional -

Aerosol Industry Standard Setter

Aerosol Industry Standard Setter

| Availability: | |

|---|---|

| Quantity: | |

QGBS-500

MEITAR

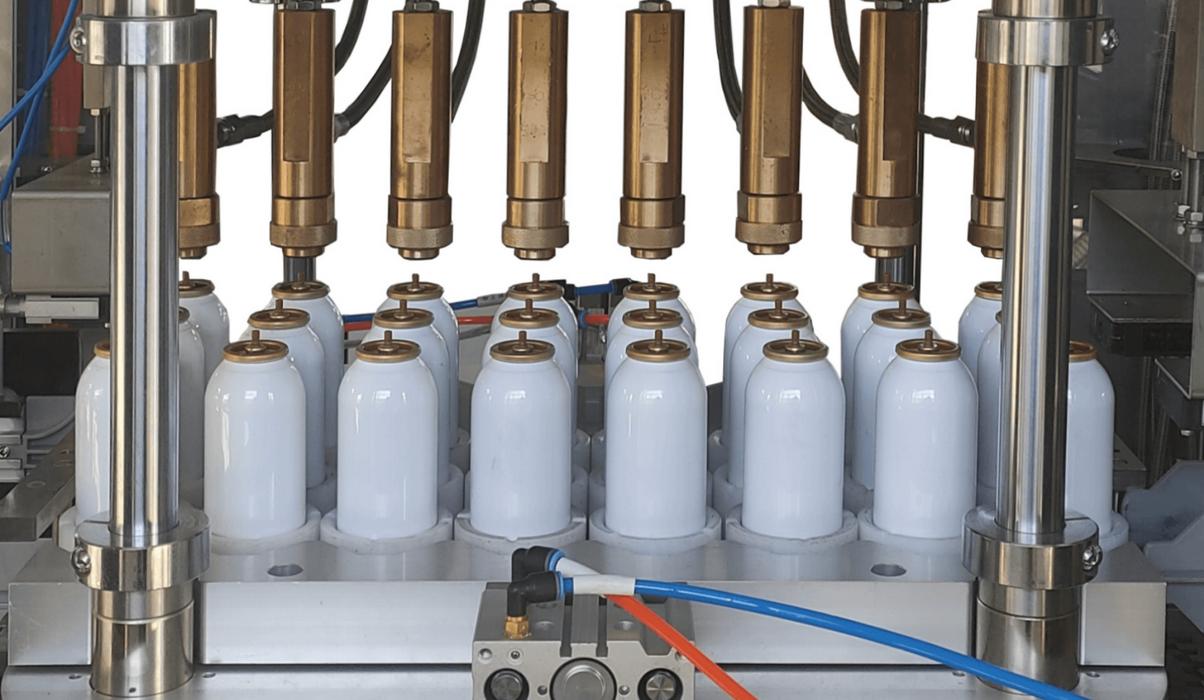

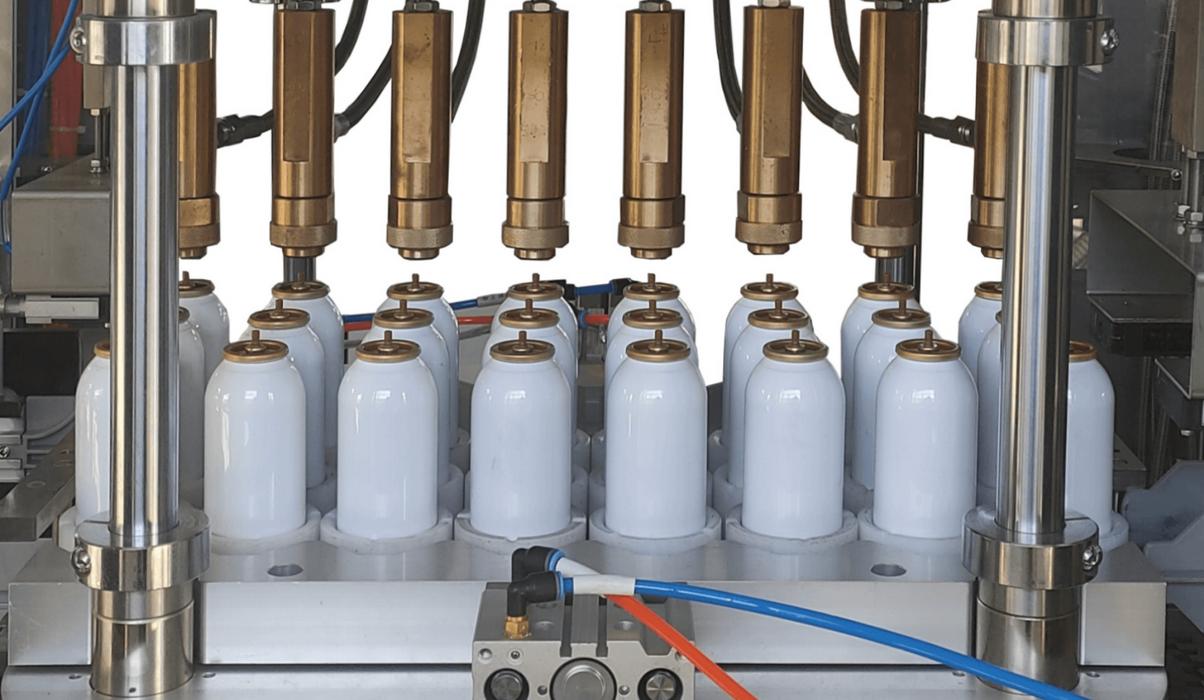

QGBS-500 3in1Semi-automatic Butane Gas Filling Machine

This machine is made of split type semi-automatic after improvement, optimization and integration.Combine vacuuming, sealing and quantitative filling on one workbench. Only one operation is needed. Three actions can be completed simultaneously at one time.Time saving, land saving, fast speed, high precision, good stability.It is the ideal equipment for laboratories and small manufacturers.

| Technical Parameters | |

| Filling Volume | 30-500ml |

| Inflating accuracy | ≤±1% |

| Capacity | 10-15cans/min |

| Applicable | 1" |

More information, picture and design layout, please contact with us.

QGBS-500 3in1Semi-automatic Butane Gas Filling Machine

This machine is made of split type semi-automatic after improvement, optimization and integration.Combine vacuuming, sealing and quantitative filling on one workbench. Only one operation is needed. Three actions can be completed simultaneously at one time.Time saving, land saving, fast speed, high precision, good stability.It is the ideal equipment for laboratories and small manufacturers.

| Technical Parameters | |

| Filling Volume | 30-500ml |

| Inflating accuracy | ≤±1% |

| Capacity | 10-15cans/min |

| Applicable | 1" |

More information, picture and design layout, please contact with us.

1 Standardized workshop of total 30,000 square meters.

2.verification Certificates of equipments: IS09001:2001; CE Certificate, SGS Certificate, Logo trademark registration, etc.

3.The machines will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of liquid and gas pipeline, and pneumatic, electrical and mechnical stability.

4. Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

5.The engineers are experienced. We can produce diferent products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

6.Professional installation team can help customers make benefits in a shortest time.

Contact Us

Enjoy and contact us for further information!

Whatsapp & WeChat: +8613626120188

Email: psh@jsmeida.com

1 Standardized workshop of total 30,000 square meters.

2.verification Certificates of equipments: IS09001:2001; CE Certificate, SGS Certificate, Logo trademark registration, etc.

3.The machines will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of liquid and gas pipeline, and pneumatic, electrical and mechnical stability.

4. Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

5.The engineers are experienced. We can produce diferent products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

6.Professional installation team can help customers make benefits in a shortest time.

Contact Us

Enjoy and contact us for further information!

Whatsapp & WeChat: +8613626120188

Email: psh@jsmeida.com