| Availability: | |

|---|---|

| Quantity: | |

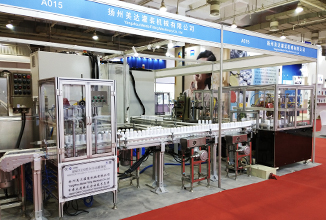

QGQZX120

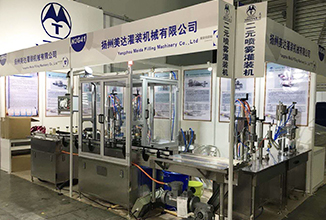

MEITAR

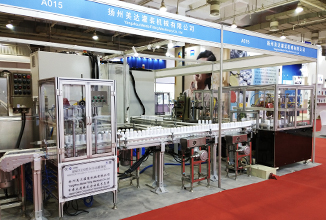

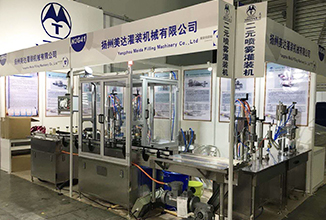

This machine is combined pneumatic control and electrical control, meanwhile coordinated with other mechanisms,

It is a whole set of circulation filling lines including can arrange machine, rotary puck inserting machine,

6 heads/12heads linear liquid filling machine, rotary type vacuum & crimping machine,

5 heads/10 heads linear type gas filling machine, linear type weighing machine, actuator presser machine,

capping machine, can unloading machine and flexible conveyor.

This line suitable for different kinds of cans, no need to change any mold,

It solves the problem that the mold needs to be replaced when occur different diameter can during production,

which greatly saves time and improves production efficiency.

| TECHNICAL | PARAMETER | |

| Filling capacity | 120cans/min | |

| Liquid Filling volume | 10-500ml | |

| Gas filling volume | 10-500ml | |

| Liquid Filling accuracy | ≤±1% | |

| Gas filling accuracy | ≤±1% | |

| Applicable can | Diameter | 35—66mm |

| Height | 75-350mm | |

| Weighing precision | ≤±1g | |

More information, picture and design layout, please contact with us.

This machine is combined pneumatic control and electrical control, meanwhile coordinated with other mechanisms,

It is a whole set of circulation filling lines including can arrange machine, rotary puck inserting machine,

6 heads/12heads linear liquid filling machine, rotary type vacuum & crimping machine,

5 heads/10 heads linear type gas filling machine, linear type weighing machine, actuator presser machine,

capping machine, can unloading machine and flexible conveyor.

This line suitable for different kinds of cans, no need to change any mold,

It solves the problem that the mold needs to be replaced when occur different diameter can during production,

which greatly saves time and improves production efficiency.

| TECHNICAL | PARAMETER | |

| Filling capacity | 120cans/min | |

| Liquid Filling volume | 10-500ml | |

| Gas filling volume | 10-500ml | |

| Liquid Filling accuracy | ≤±1% | |

| Gas filling accuracy | ≤±1% | |

| Applicable can | Diameter | 35—66mm |

| Height | 75-350mm | |

| Weighing precision | ≤±1g | |

More information, picture and design layout, please contact with us.

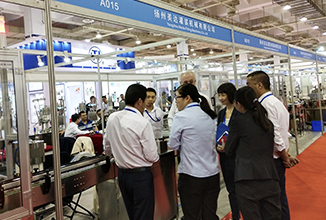

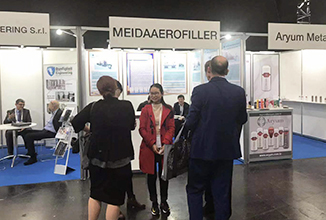

Company Information

1 Standardized workshop of total 30,000 square meters.

2.verification Certificates of equipments: IS09001:2001; CE Certificate, SGS Certificate, Logo trademark registration, etc.

3.The machines will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of liquid and gas pipeline, and pneumatic, electrical and mechnical stability.

4. Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

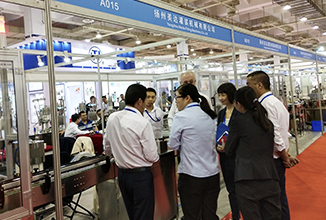

5.The engineers are experienced. We can produce diferent products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

6.Professional installation team can help customers make benefits in a shortest time.

Contact Us

Enjoy and contact us for further information!

Whatsapp & WeChat: +8613626120188

Email: psh@jsmeida.com

Company Information

1 Standardized workshop of total 30,000 square meters.

2.verification Certificates of equipments: IS09001:2001; CE Certificate, SGS Certificate, Logo trademark registration, etc.

3.The machines will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of liquid and gas pipeline, and pneumatic, electrical and mechnical stability.

4. Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

5.The engineers are experienced. We can produce diferent products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

6.Professional installation team can help customers make benefits in a shortest time.

Contact Us

Enjoy and contact us for further information!

Whatsapp & WeChat: +8613626120188

Email: psh@jsmeida.com

Our Service

1.One year warranty .

2.Engineers available to service machinery overseas;

3.Professional sellers are always at your service;

4.We can provide customer factory plan,layout, installation,training and so on.

Our Service

1.One year warranty .

2.Engineers available to service machinery overseas;

3.Professional sellers are always at your service;

4.We can provide customer factory plan,layout, installation,training and so on.

| | Address: 50 Huiqi Road, Yangzhou |

| | Sales: 86-13626120188 |

| | Main: 86-0514-86371188 |

| | E-mail: psh@jsmeida.com |