PREV

NEXT

-

Focused And Therefore Professional

Focused And Therefore Professional -

Aerosol Industry Standard Setter

Aerosol Industry Standard Setter

Views: 4 Author: Site Editor Publish Time: 2021-06-14 Origin: Site

All along, the filling machine is a solid backing in the market. And in today’s market, with people’s requirements for product quality, enterprise’s requirements for automation are getting higher and higher, and the market demand continues to expand, the under-cap filling machine has become one of the most popular filling equipment. And with the continuous development of science and technology, the domestics under-cap filling machine industry has also achieved rapid development. Its technical level, quality and equipment performance and other aspects have been greatly improved, in support of enterprise safety and efficient production have played an extremely important role. Then, let us introduce in detail what is the main use of the under cap filling machine.

Here is the content list:

l Introduction of the under cap filling machine

l The purpose of the under cap filling machine

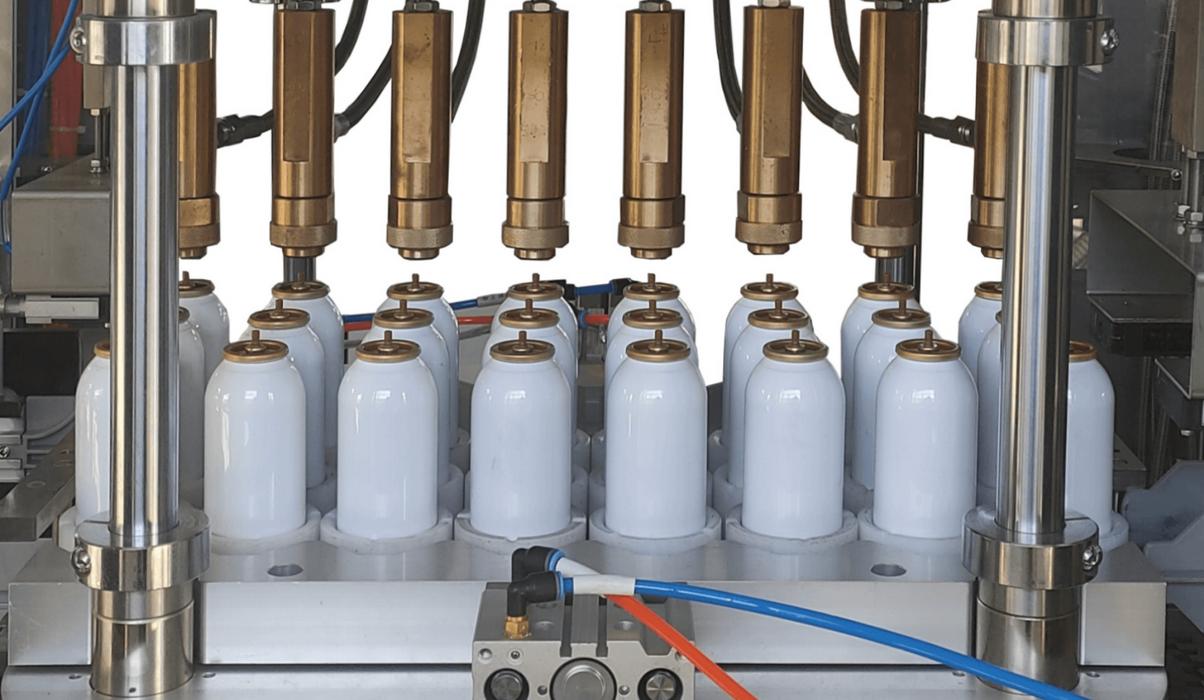

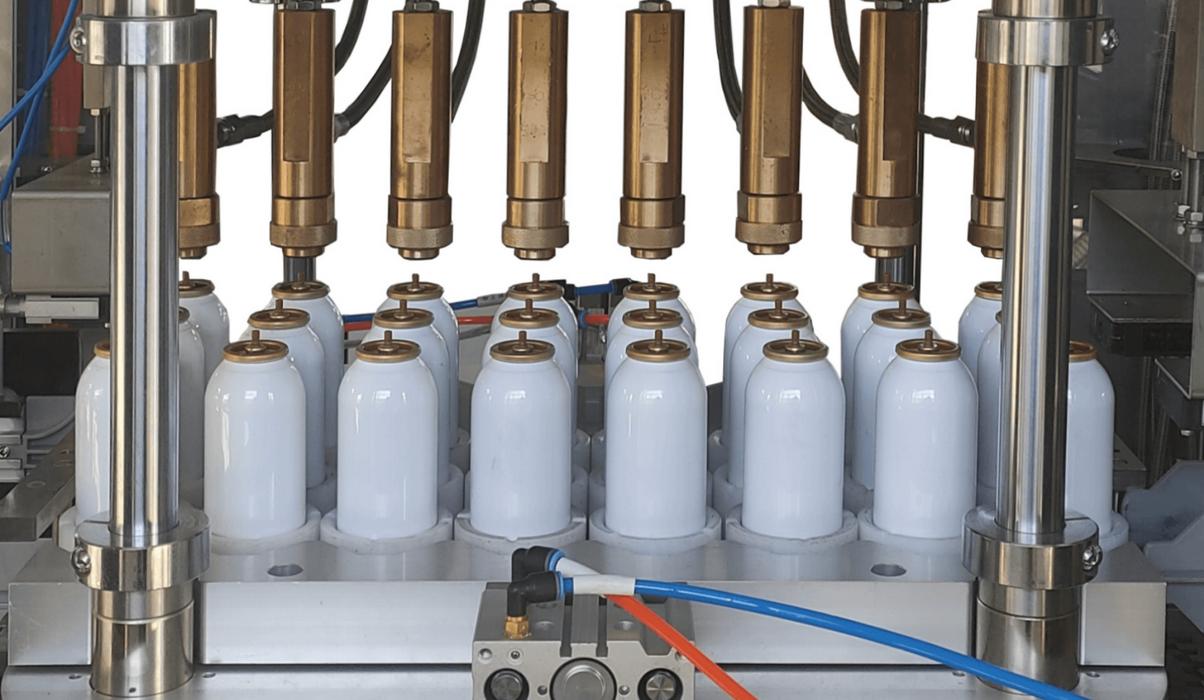

The under cap filling machine is composed of a liquid metering cylinder and a charging head. The liquid metering cylinder and gas metering cylinder are fixed on the rear of the table surface. The filling head, sealing machine and charging head are installed on the platform plate of the lifting column. It is convenient to adjust up and down according to the different heights of the tank. The booster pump adopts the latest double-in-double-out efficient mode, and increases the caliber of the inlet and outlet pipeline.

Under the cap filling machine is different from the ordinary aerosol filling machine, it can be filled at the same time,sealing and vacuum pumping. The under-cap filling machine can satisfy the production and filling of all non-core closed valve products. When it is filling,the product must be completed in a vacuum and must be sealed immediately after filling from under the manless valve cover. And it also has a device to recycle leftover material, so it can avoid waste. At the same time, under the cap filling machine can not only vacuum, raw material filling and sealing at one time, but also can be used as a sealing machine, with multiple functions.

The machine integrates vacuum pumping, quantitative filling, sealing and recovery in one. It is special equipment for sealing immediately after filling under the valve cover (without core valve)under the vacuum condition. The machine is easy to operate, good sealing air tightness, accurate measurement, etc. At present, the machine can be used for refrigerant(F12, F22, F134a), quantitative valve air freshener, air conditioning lubricating oil, mountain tourism with liquefied gas tank filling products.

Because aerosol technology is gradually mature, the under cap filling machine is more and more diversified, the application of filling machine under cover is auto refrigerant products, portable oxygen tank, canned air, such as no core valve can be used to filling. In addition, there are dual packing products, first by filling machine the cover sealing valve pocket, then priming.

Nowadays, with the continuous development of technology, the development of the cap filling machine is more mature. I believe that we have learned what is the purpose of the cap filling machine through the introduction of what. People can choose a suitable machine from Yangzhou Meida Company, which is the best choice.

Come to our website to check out more aerosol filling machines and Bov aerosol filling machines!