PREV

NEXT

-

Focused And Therefore Professional

Focused And Therefore Professional -

Aerosol Industry Standard Setter

Aerosol Industry Standard Setter

Views: 4 Author: Site Editor Publish Time: 2022-06-20 Origin: Site

The accessories of the aerosol filling machine itself: mainly the sealing rings and Y-rings of some wearing parts. The auxiliary accessories needed in the production of aerosol products are: internal pressure measuring table, aerosol filling and sealing depth, diameter measuring table, and aerosol filling contact height measuring table. These three tables are a must when producing aerosol products.

How to test the quality of products produced by aerosol filling machine?

What should be paid attention to in the production of aerosol filling machine?

How is the current market for aerosol filling machines?

1. Non-quantitative valve aerosol: Take 4 bottles of the test sample, press the valve for a few seconds to spray, wipe it, accurately weigh it, put it in a 25+1 ℃ water bath for half an hour, take it out, wipe it dry, and press the valve to continue to spray accurately 5 minutes, wipe it off, weigh it separately, and then put it in a 25+1℃ water bath, repeat the operation 3 times according to the above method, calculate the average spray rate of each bottle in g/s, and the average spray rate of each bottle produced by aerosol filling machine should be Comply with the regulations under each category.

2. Quantitative valve aerosol: Take 4 bottles of the test sample, spray several times, wipe clean, accurately weigh, spray once, wipe clean, and then accurately weigh, the difference between the two weights before and after is the amount of one spray , after measuring the spray volume for 3 times according to the above method, spray continuously for 10 times regardless of the weight; then measure the spray volume continuously for 3 times according to the above method, and then spray continuously for 10 times regardless of the weight, and finally measure the spray volume for 4 times according to the above method quantity. Calculate the average value of 10 sprays before and after each bottle and compare it with the marked spray, and the difference limit should be within +20% of the marked spray.

Preparation and dispensing of drugs

The aerosol filling machine is produced according to the prescription composition and the type of aerosol required. Solution-type aerosols should be made into clear liquids; suspension-type aerosols should be micronized and kept dry; emulsion-type aerosols should be made into stable emulsions. Quantitatively distribute the above-prepared qualified drug dispersion system into the prepared container, install the valve, and fasten the sealing cap.

According to statistics, in the total amount of aerosols, daily aerosols account for a high proportion and the usage is increasing year by year, which makes the demand for aerosol filling machines grow rapidly. Other products that can be cross-applied include window cleaners, furniture polishes, fire extinguishers, lubricants, vinyl trim cleaners, and water repellent aerosols, which are used in car care aerosols when these cross-cutting products are taken into account The total is very impressive. aerosol filling machine is an indispensable machine in the production process of aerosol products. The large demand for aerosol also requires the continuous improvement of filling technology of aerosol filling machines.

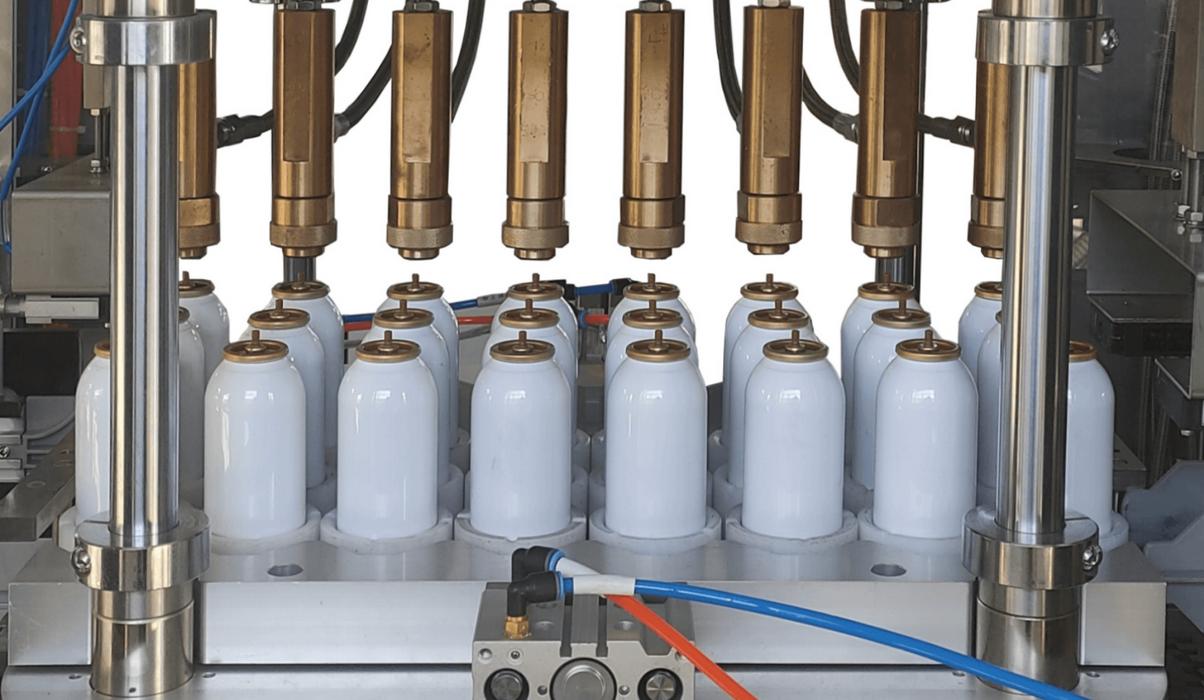

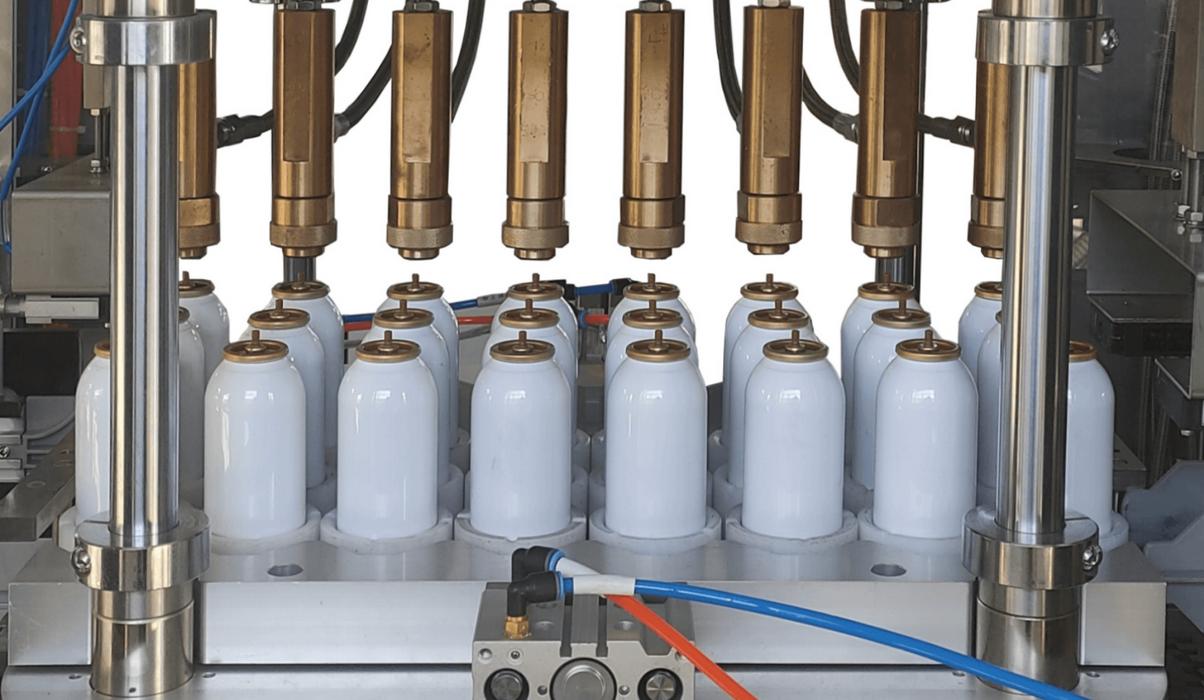

The aerosol filling machines have been used in many fields. Yangzhou Meida Filling Machinery Co.,Ltd maintains close relationships with customers in aerosol filling machine industry, and is committed to strengthening production and operation, improving quality and safety.