PREV

NEXT

-

Focused And Therefore Professional

Focused And Therefore Professional -

Aerosol Industry Standard Setter

Aerosol Industry Standard Setter

| Availability: | |

|---|---|

| Quantity: | |

QGQ750

MEITAR

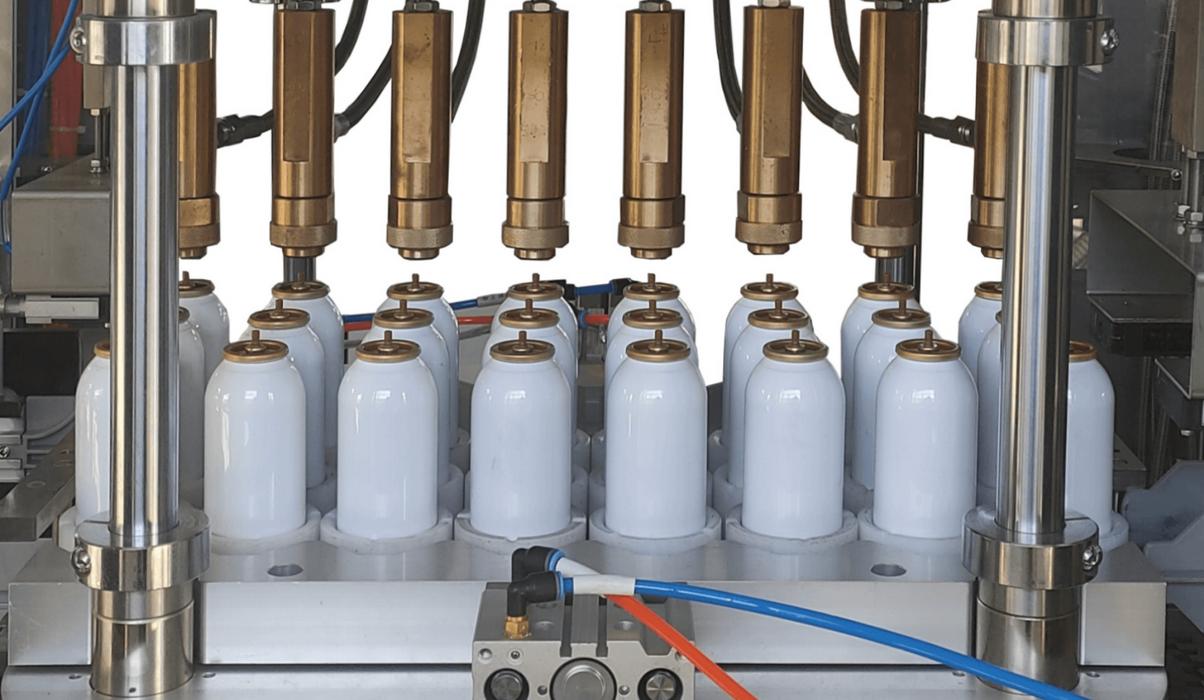

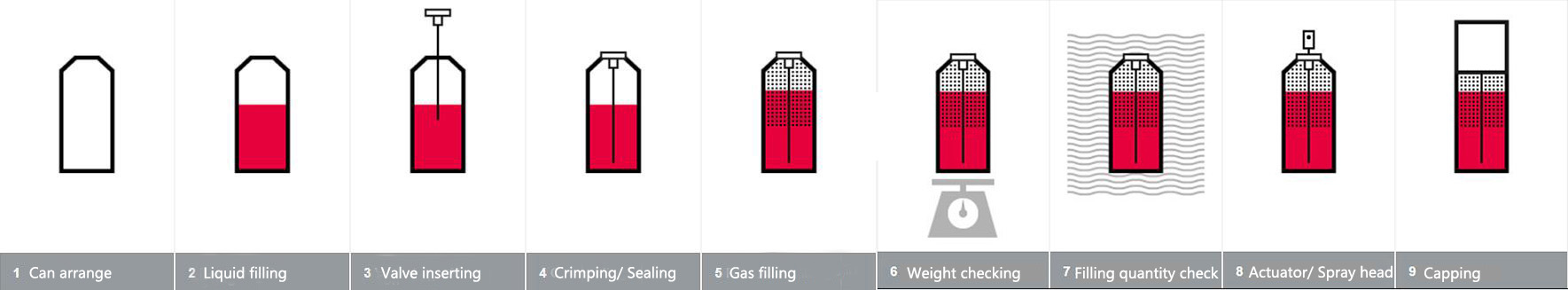

Automatic Insecticide QGQ750 Aerosol Filling Machine consist of 1cans arranging machine, 2 liquid filling machine, 3 valve sorting & inserting machine, 4 valve crimping and gas filling machine, 5 automatic weighing machine, 6 water bath leakage tester, 7 actuator presser, 8 capping machine, 9 ink jet printer, 10 packing table, etc. Propellants could be LPG, DME, CO2, N2, compressed air, etc,

Widely applied in spray paint, air freshener, insecticide, body spray, car care spray, cosmetics, food aerosols etc

Technical Parameter

Production capacity: 2400-3600cans/h

Liquid filling capacity: 30-750ml Gas filling capacity: 30-750ml

Filling accuracy≤±1% Sealing accuracy≤0.3%

Air pressure: 0.8-1Mpa Max. Air Consumption 3-5m3/min

Applicable can Diameter 35-71mm Applicable can Height 85-330mm

The factory is a member of China spray packaging industry group, is specialized in the development of various aerosol filling equipment, engineering design, installation and debugging and technical training and service of professional enterprises.

With perfect management mode, strong technical force, advanced technology and equipment, professional processing equipment, precise detection means, warm and thoughtful service.

QQG 750 automatic aerosol filling machine is our factory according to the current aerosol development status and national conditions, perfect absorption of the western developed countries today's advanced technology, collection of meida for many years engaged in aerosol filling equipment manufacturing wisdom crystallization gradually developed.

1.The control part of the machine adopts pneumatic components imported from Italy and Japan, and the host device perfectly absorbs advanced technology from Germany.

2.The main machine parts are processed by CNC machine tools.

3.It has the advantages of high production efficiency, stable performance, high precision of repeated filling and convenient operation and adjustment.

4.The conveying part of the machine is driven by explosion-proof motor.

5.Power requirement: 380V 50HZ

6.The main engine part adopts pneumatic control.

7.Power requirements: equipped with air compressor:

8. displacement ≥1.0m³/ min,

9.output pressure ≥ 0.8-1.0mpa.

Details Images

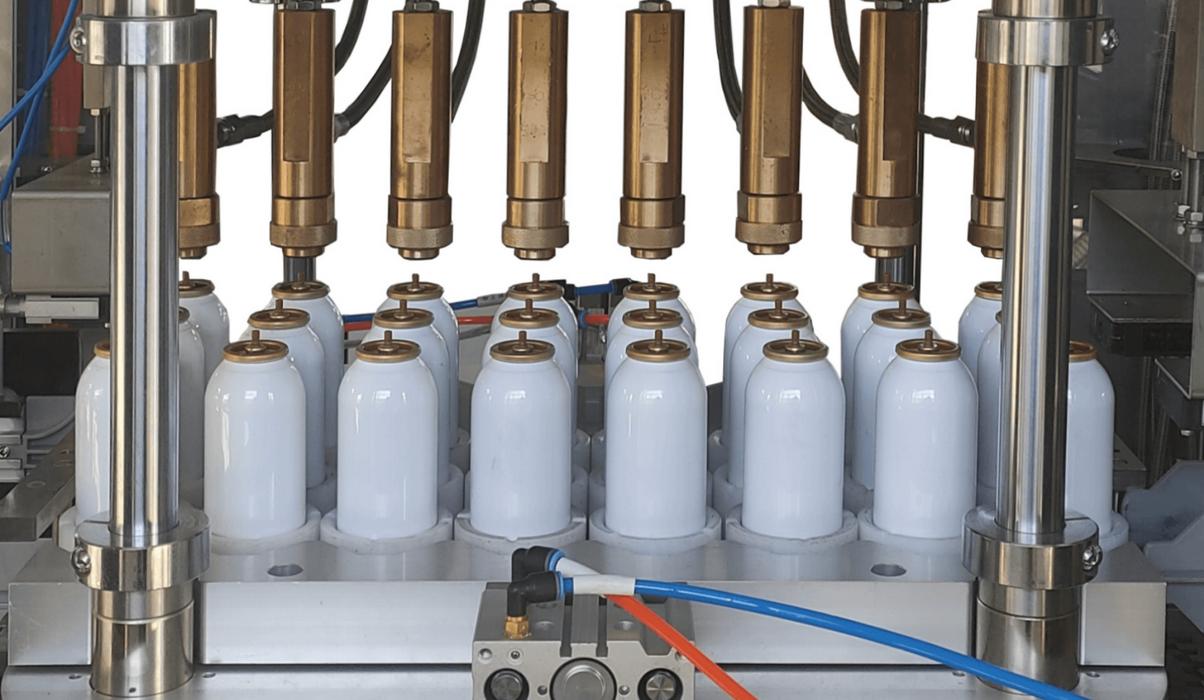

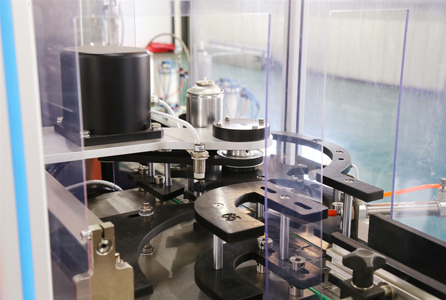

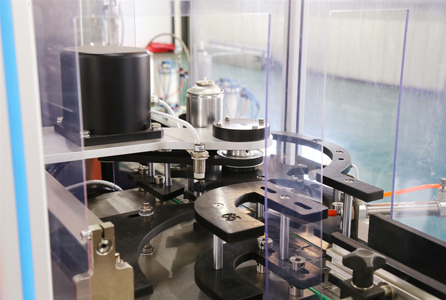

Liquid Filling machine

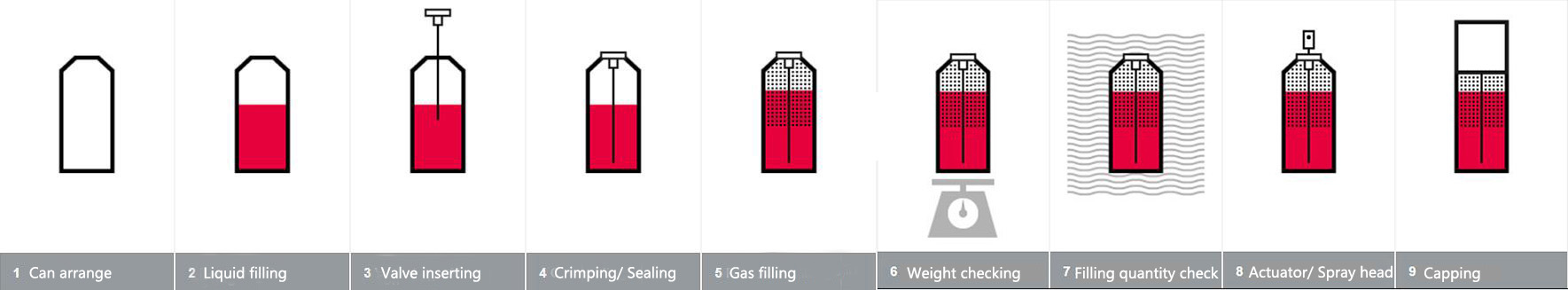

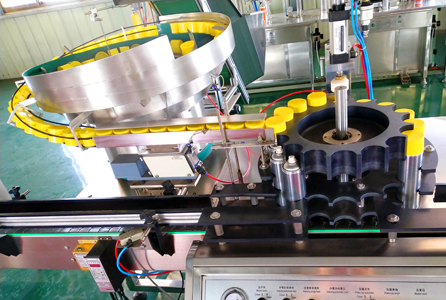

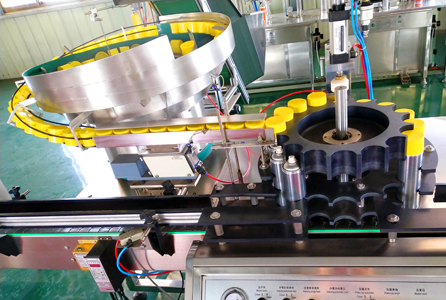

Sealing & gas filling machine

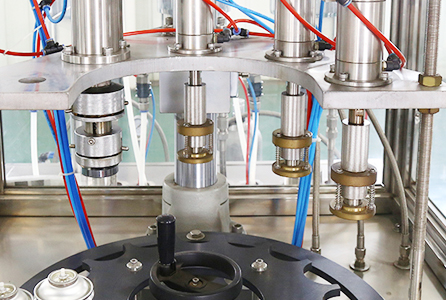

Automatic Weighing machine

Water bath leakage tester

Actuator Presser

Capping machine

ink jet printer

More information, picture and design layout, please contact with us.

Automatic Insecticide QGQ750 Aerosol Filling Machine consist of 1cans arranging machine, 2 liquid filling machine, 3 valve sorting & inserting machine, 4 valve crimping and gas filling machine, 5 automatic weighing machine, 6 water bath leakage tester, 7 actuator presser, 8 capping machine, 9 ink jet printer, 10 packing table, etc. Propellants could be LPG, DME, CO2, N2, compressed air, etc,

Widely applied in spray paint, air freshener, insecticide, body spray, car care spray, cosmetics, food aerosols etc

Technical Parameter

Production capacity: 2400-3600cans/h

Liquid filling capacity: 30-750ml Gas filling capacity: 30-750ml

Filling accuracy≤±1% Sealing accuracy≤0.3%

Air pressure: 0.8-1Mpa Max. Air Consumption 3-5m3/min

Applicable can Diameter 35-71mm Applicable can Height 85-330mm

The factory is a member of China spray packaging industry group, is specialized in the development of various aerosol filling equipment, engineering design, installation and debugging and technical training and service of professional enterprises.

With perfect management mode, strong technical force, advanced technology and equipment, professional processing equipment, precise detection means, warm and thoughtful service.

QQG 750 automatic aerosol filling machine is our factory according to the current aerosol development status and national conditions, perfect absorption of the western developed countries today's advanced technology, collection of meida for many years engaged in aerosol filling equipment manufacturing wisdom crystallization gradually developed.

1.The control part of the machine adopts pneumatic components imported from Italy and Japan, and the host device perfectly absorbs advanced technology from Germany.

2.The main machine parts are processed by CNC machine tools.

3.It has the advantages of high production efficiency, stable performance, high precision of repeated filling and convenient operation and adjustment.

4.The conveying part of the machine is driven by explosion-proof motor.

5.Power requirement: 380V 50HZ

6.The main engine part adopts pneumatic control.

7.Power requirements: equipped with air compressor:

8. displacement ≥1.0m³/ min,

9.output pressure ≥ 0.8-1.0mpa.

Details Images

Liquid Filling machine

Sealing & gas filling machine

Automatic Weighing machine

Water bath leakage tester

Actuator Presser

Capping machine

ink jet printer

More information, picture and design layout, please contact with us.

Company Information

1 Standardized workshop of total 30,000 square meters.

2.verification Certificates of equipments: IS09001:2001; CE Certificate, SGS Certificate, Logo trademark registration, etc.

3.The machines will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of liquid and gas pipeline, and pneumatic, electrical and mechnical stability.

4. Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

5.The engineers are experienced. We can produce diferent products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

6.Professional installation team can help customers make benefits in a shortest time.

Contact Us

Enjoy and contact us for further information!

Whatsapp & WeChat: +8613626120188

Email: psh@jsmeida.com

Company Information

1 Standardized workshop of total 30,000 square meters.

2.verification Certificates of equipments: IS09001:2001; CE Certificate, SGS Certificate, Logo trademark registration, etc.

3.The machines will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of liquid and gas pipeline, and pneumatic, electrical and mechnical stability.

4. Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

5.The engineers are experienced. We can produce diferent products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

6.Professional installation team can help customers make benefits in a shortest time.

Contact Us

Enjoy and contact us for further information!

Whatsapp & WeChat: +8613626120188

Email: psh@jsmeida.com

Our Service

1.One year warranty .

2.Engineers available to service machinery overseas;

3.Professional sellers are always at your service;

4.We can provide customer factory plan,layout, installation,training and so on.

Our Service

1.One year warranty .

2.Engineers available to service machinery overseas;

3.Professional sellers are always at your service;

4.We can provide customer factory plan,layout, installation,training and so on.

FAQ

Q1:Are you a factory or trading company?

A1: We are a factory specialized in aerosol filling machine, such as spray print, insecticide, ect.

Q2:Where is your factory location? How can I visit there?

A2:Meida Filling Machinery CO.,LTD is located in Yangzhou, China. You could visit us by air to Yangzhou Airport then we will pick you up to our factory.

Q3:How does your factory do regarding quality control?

A3:Quality is priority. People from Meitar always attach great importance to quality controlling from the beginning to the end.

we support to inspect machine before shipment Our factory has gained TUV and ISO authentication.

Q4:What's the guarantee if we purchase from you?

A4:All the equipment ordered from us will provide one year guarantee from the delivery date .If there is any wearing part be broken within the warranth and isn't caused by improperly operation then we would offer then new parts for free.

Q5:How about the after service?

A5:There's no problem we could send our engineer to install or fix the machine locally in due course but customer need to pay the round air tickets cost and arrange the hotel accommodation for our engineer.

Welcome you to contact us if you have any questions!

FAQ

Q1:Are you a factory or trading company?

A1: We are a factory specialized in aerosol filling machine, such as spray print, insecticide, ect.

Q2:Where is your factory location? How can I visit there?

A2:Meida Filling Machinery CO.,LTD is located in Yangzhou, China. You could visit us by air to Yangzhou Airport then we will pick you up to our factory.

Q3:How does your factory do regarding quality control?

A3:Quality is priority. People from Meitar always attach great importance to quality controlling from the beginning to the end.

we support to inspect machine before shipment Our factory has gained TUV and ISO authentication.

Q4:What's the guarantee if we purchase from you?

A4:All the equipment ordered from us will provide one year guarantee from the delivery date .If there is any wearing part be broken within the warranth and isn't caused by improperly operation then we would offer then new parts for free.

Q5:How about the after service?

A5:There's no problem we could send our engineer to install or fix the machine locally in due course but customer need to pay the round air tickets cost and arrange the hotel accommodation for our engineer.

Welcome you to contact us if you have any questions!