| Availability: | |

|---|---|

| Quantity: | |

QGQ750

MEITAR

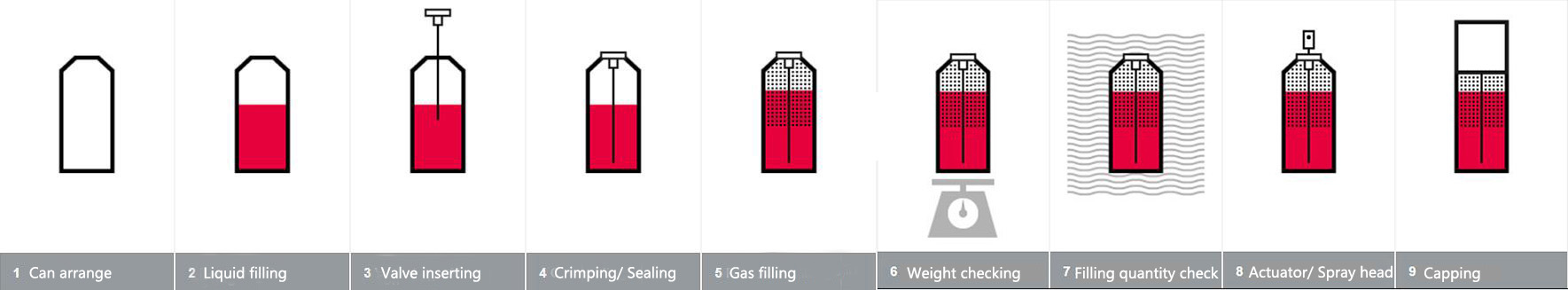

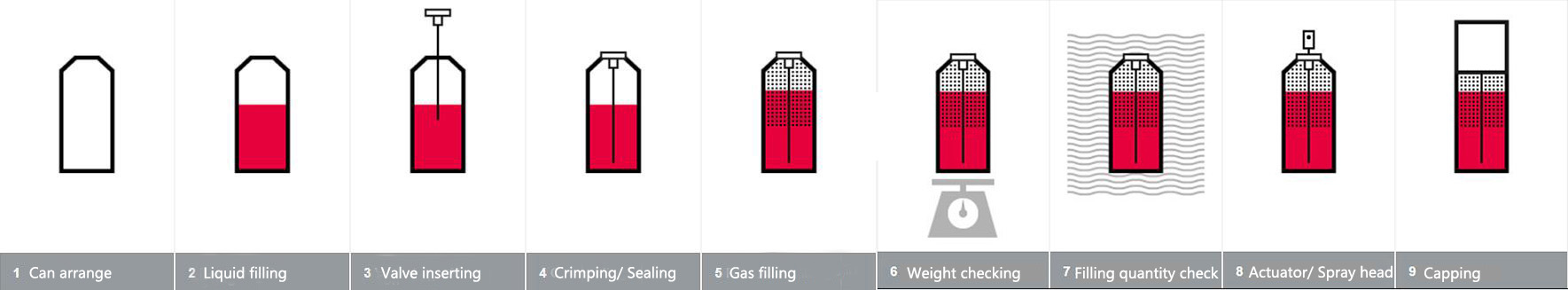

Automatic Rust Resistant Spray Filling Machine Production Line consist of 1cans arranging machine, 2 liquid filling machine, 3 valve sorting & inserting machine, 4 valve crimping and gas filling machine, 5 automatic weighing machine, 6 water bath leakage tester, 7 actuator presser, 8 capping machine, 9 ink jet printer, 10 packing table, etc. Propellants could be LPG, DME, CO2, N2, compressed air, etc.

Widely applied in spray paint, air freshener, insecticide, body spray, car care spray, cosmetics, food aerosols etc.

When the equipment is assembled, the star wheel device of aerosol canister φ65 is installed.

The specific configuration of the machine can be customized according to the actual needs of customers.

The commonly used star wheel replacement parts are φ35, φ40, φ45, φ50, φ53, φ57, φ65 and so on.

Customers can choose by themselves.

Technical Parameter

Production capacity: 2400-3600cans/h

Liquid filling capacity: 30-750ml Gas filling capacity: 30-750ml

Filling accuracy≤±1% Sealing accuracy≤0.3%

Air pressure: 0.8-1Mpa Max. Air Consumption 3-5m3/min

Applicable can Diameter 35-71mm Applicable can Height 85-330mm

Details Images

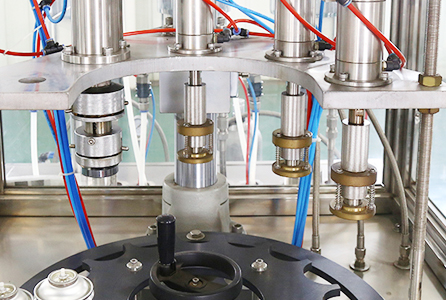

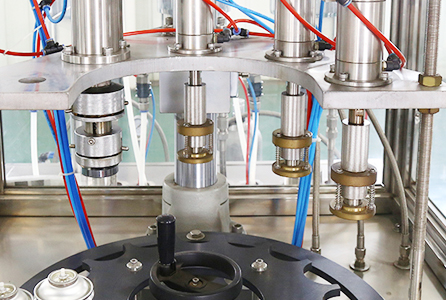

Liquid Filling machine Sealing & gas filling machine

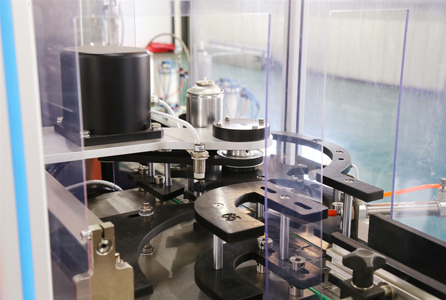

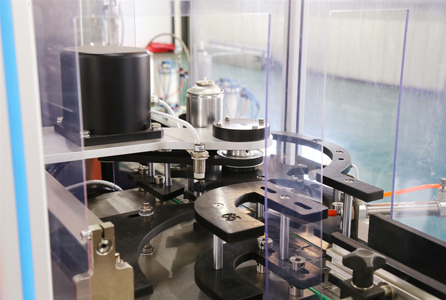

Automatic Weighing machine Water bath leakage tester

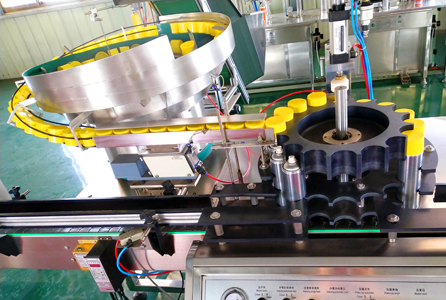

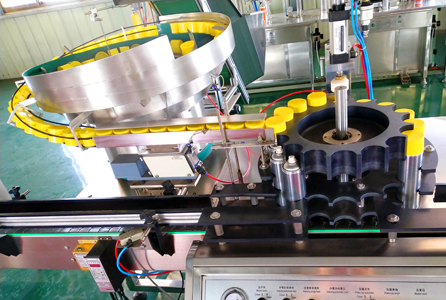

Actuator Presser Capping machine

ink jet printer

More information, picture and design layout, please contact with us.

Automatic Rust Resistant Spray Filling Machine Production Line consist of 1cans arranging machine, 2 liquid filling machine, 3 valve sorting & inserting machine, 4 valve crimping and gas filling machine, 5 automatic weighing machine, 6 water bath leakage tester, 7 actuator presser, 8 capping machine, 9 ink jet printer, 10 packing table, etc. Propellants could be LPG, DME, CO2, N2, compressed air, etc.

Widely applied in spray paint, air freshener, insecticide, body spray, car care spray, cosmetics, food aerosols etc.

When the equipment is assembled, the star wheel device of aerosol canister φ65 is installed.

The specific configuration of the machine can be customized according to the actual needs of customers.

The commonly used star wheel replacement parts are φ35, φ40, φ45, φ50, φ53, φ57, φ65 and so on.

Customers can choose by themselves.

Technical Parameter

Production capacity: 2400-3600cans/h

Liquid filling capacity: 30-750ml Gas filling capacity: 30-750ml

Filling accuracy≤±1% Sealing accuracy≤0.3%

Air pressure: 0.8-1Mpa Max. Air Consumption 3-5m3/min

Applicable can Diameter 35-71mm Applicable can Height 85-330mm

Details Images

Liquid Filling machine Sealing & gas filling machine

Automatic Weighing machine Water bath leakage tester

Actuator Presser Capping machine

ink jet printer

More information, picture and design layout, please contact with us.

Company Information

1 Standardized workshop of total 30,000 square meters.

2.verification Certificates of equipments: IS09001:2001; CE Certificate, SGS Certificate, Logo trademark registration, etc.

3.The machines will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of liquid and gas pipeline, and pneumatic, electrical and mechnical stability.

4. Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

5.The engineers are experienced. We can produce diferent products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

6.Professional installation team can help customers make benefits in a shortest time.

Contact Us

Enjoy and contact us for further information!

Whatsapp & WeChat: +8613626120188

Email: psh@jsmeida.com

Company Information

1 Standardized workshop of total 30,000 square meters.

2.verification Certificates of equipments: IS09001:2001; CE Certificate, SGS Certificate, Logo trademark registration, etc.

3.The machines will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of liquid and gas pipeline, and pneumatic, electrical and mechnical stability.

4. Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

5.The engineers are experienced. We can produce diferent products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

6.Professional installation team can help customers make benefits in a shortest time.

Contact Us

Enjoy and contact us for further information!

Whatsapp & WeChat: +8613626120188

Email: psh@jsmeida.com

Our Service

1.One year warranty .

2.Engineers available to service machinery overseas;

3.Professional sellers are always at your service;

4.We can provide customer factory plan,layout, installation,training and so on.

Our Service

1.One year warranty .

2.Engineers available to service machinery overseas;

3.Professional sellers are always at your service;

4.We can provide customer factory plan,layout, installation,training and so on.

| | Address: 50 Huiqi Road, Yangzhou |

| | Sales: 86-13626120188 |

| | Main: 86-0514-86371188 |

| | E-mail: psh@jsmeida.com |